Direct Flame Hot Rubber Crack Fillers & Sealers

Crack Sealers for Direct Flame Melters are more forgiving during the heating process and are designed specifically for this type of heating and melting for your parking lot crack repair. Direct flame sealants are not always agitated and their limits are often pushed by overheating and greatly fluctuating temperatures during application. Most direct fire hot melters are challenged to maintain consistent temperature and so using crack fillers and sealers designed for this specifically is imperative. If you use other hot pour products that were designed for oil jacketed units in direct fired kettles you find that over heating can harm these materials causing problems with end products and the result can be very challenging. Tracking and flow problems or even separation in cold temperatures can be the result of not using the right material for the job. We have provided a nice assortment of quality direct flame sealants for you to choose from. New in this category are product formulas containing recycled materials and can provide you with comfort that you are doing your part in moving toward a more eco-friendly existence. Most recently and beyond the movement to simply provide all environmentally friendly products, but with a balance on the side of making sure the quality remains at a higher level, there has been some development in recycled products using quality reclaimed Roof Shingle Materials and Recycled Asphalt Materials. These recycled contents can enhance a products strength and have some admirable and superior qualities. Watch for some new alternatives in this space that we will soon present.

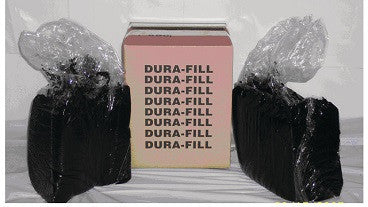

Hot Pour Fillers & Sealers for Commercial Use are designed for use with Direct Flame Equipment